A. SCOPE

This specification applies piezo buzzer, FSD-1440H

B. SPECIFICATION

| No. | Item | Unit | Specification | Condition |

1 | Oscillation Frequency | Hz | 4000 | Square Wave |

2 | Operating Voltage | Vp-p | 1~25 | |

3 | Rated Voltage | Vp-p | 5 | |

4 | Current Consumption | mA | MAX. 5 | at Rated Voltage |

5 | Sound Pressure Level | dB | MIN. 80 | at 10cm at Rated Voltage |

6 | Electrostatic Capacity | pF | 15000±30% | at 100Hz 1V |

7 | Operating Temperature | ℃ | -30~ +85 | |

8 | Storage Temperature | ℃ | -40 ~ +85 | |

9 | Dimension | mm | 14.1 x 14.1 x H4.1 | See appearance drawing |

10 | Weight (MAX) | gram | 1.2 | |

11 | Housing Material | LCP(Black ) | ||

12 | Leading Pin | Plated Brass(Au) | See appearance drawing | |

13 | Environmental | RoHS |

C. APPEARANCE DRAWING

Tol : ± 0.5 Unit: mm

D.TESTING METHOD

Standard Measurement conditions

Temperature:25±2℃ Humidity:45-65%

Acoustic Characteristics:

The oscillation frequency, current consumption and sound pressure are measured by the measuring instruments shown below

In the measuring test, buzzer is placed as follows:

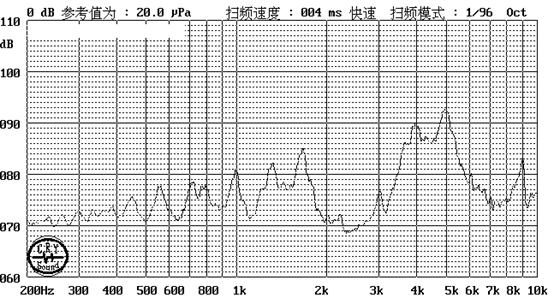

E. Typical Frequency Response Curve

F. Soldering Condition

(1)Recommendable reflow soldering condition is as follows

(Reflow soldering is twice)

Note:It is requested that reflow soldering should be executed after heat of product goes down to normal.

Heat resistant line

(Used when heat resistant reliability test is performed)

(2)Manual soldering

Manual soldering temperature 350 ℃ within 5 sec.

G. RELIABILITY TEST

NO. | ITEM | TEST CONDITION AND REQUIREMENT |

1 | High Temperature Test | At + 85℃ input 9 Vp-p for 240 hours. |

2 | Low Temperature Test | At -25℃ input 9 Vp-p for 240 hours. |

3 | High Temperature | After being placed in a chamber with +85℃ for 240 hours and then being placed in normal condition for 2 hours. |

4 | Low Temperature | After being Placed in a chamber with -40℃ for 240 hours and then being placed in normal condition for 2 hours. |

5 | Temperature &Humidity Cycle Test | The receiver shall be cycle 5 times through as follows: a: 90-100% R.H Allowable variation of SPL after test: |

6 | Thermal Shock | The part shall be subjected to 1000 cycles. One cycle shall be consist of: Allowable variation of SPL after test: |

7 | Vibration Test | with 10 ~ 200 ~10 Hz sin-wave sweep 15min. 49m/sec2 (constant) X,Y,Z 3 direction 2 hours each total 6 hours. |

8 | Fixed Drop Test | Fix on jig then drop from 152cm heigh to the concrete floor X,Y,Z 6 direction 5 times each total 30 times. |

9 | Room Temperature Test | At Room temp input 9 Vp-p for 240 hours. |

10 | DC Voltage Test | DC 2.53V for 1 hour. |

11 | Solderability | Pretreatment : 40 ℃ 90-95% R.H 240 hours. |

TEST CONDITION.

Standard Test Condition : a) Temperature : +5 ~ +35℃ b) Humidity : 45-85% c) Pressure : 860-1060mbar

Judgment Test Condition : a) Temperature : +25 ± 2℃ b) Humidity : 60-70% c) Pressure : 860-1060mbar

H. PACKING STANDARD

聯系人:吳經理

手機:15722819198

電話:

傳真:

郵箱: